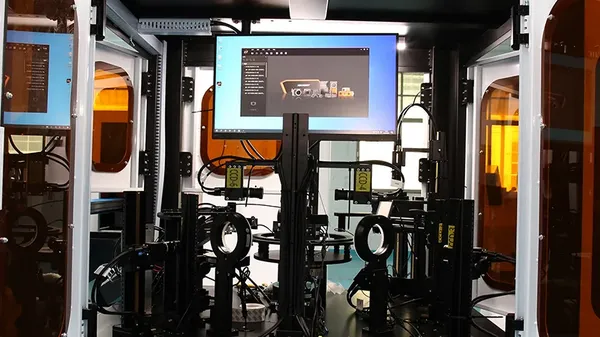

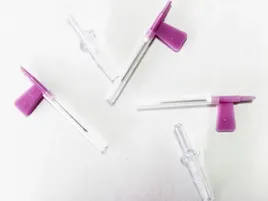

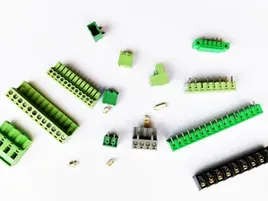

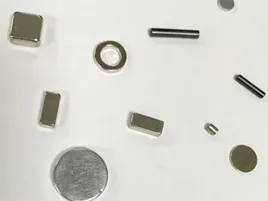

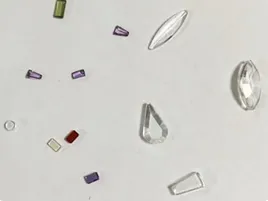

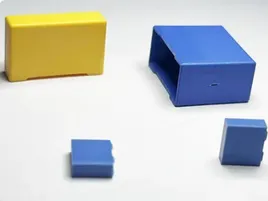

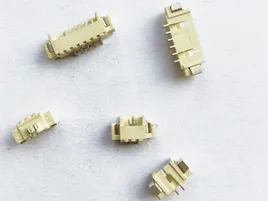

Every CKW vision inspection system consists of two main parts: the feeding module and the core inspection unit. Our intelligent vision sorting machines are built for precision, speed, and reliability making them the trusted choice for automated quality control.

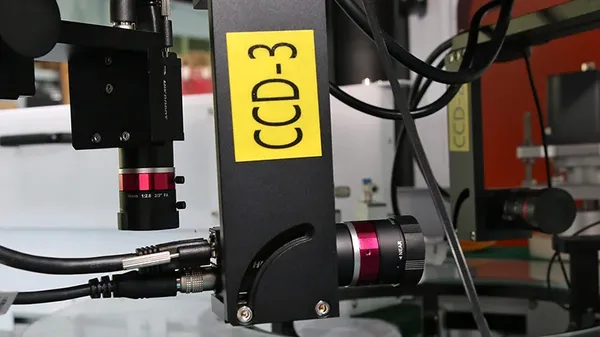

The vision inspection system uses a vibratory bowl feeder to ensure smooth and stable part handling. The machine is equipped with high-resolution CCD industrial cameras and integrated with our proprietary 360° AI-powered vision inspection software.

Depending on your product and quality requirements, the system can perform high-speed detection of key dimensions including inner and outer diameters, height, and other critical measurements ensuring they match your engineering drawings. At the same time, it can detect surface defects such as stains, bumps, and material voids with remarkable consistency.