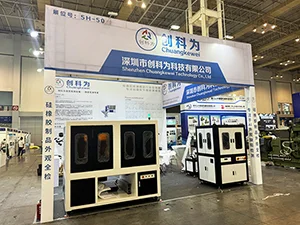

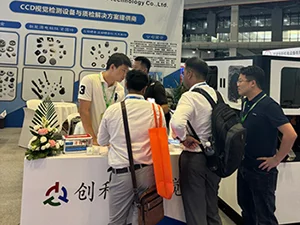

Shenzhen CKW-Group has spent more than a decade advancing optical vision inspection technology. Each milestone represents a step forward in our mission to drive quality for manufacturers worldwide.

- 2012 The founder of Shenzhen CKW-Group began a deep journey into optical inspection technology, laying the groundwork for what would become a leading force in quality control for Chinese manufacturing.

- 2014 After two years of intensive development, our vision inspection systems gained rapid market share in the fast-growing electronics and communications industry, securing nearly 50% of the sector. We also established offices in Jiangsu and Hangzhou, Zhejiang.

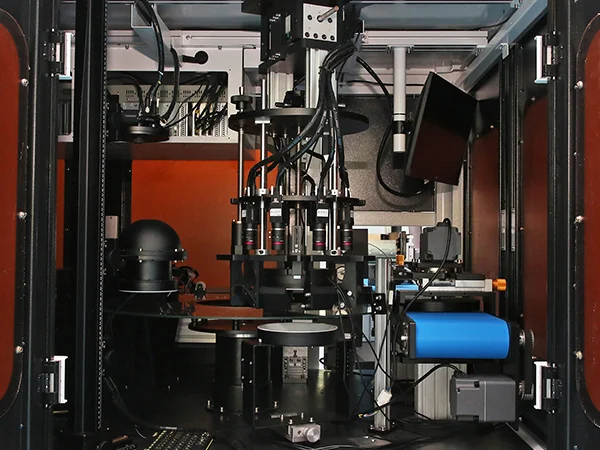

- 2016 Optical inspection was successfully introduced to the plastics industry, with our automated visual sorting systems entering full-scale production.

- 2018 As the medical sector surged, CKW-Group led the way in AI-based surface defect detection. We pioneered defect sorting technology and secured multiple invention patents.

- 2019 We expanded into magnetic materials, powder metallurgy, and ceramic components broadening our industry coverage and entering mass production. That same year, we opened our Zhengzhou office.

- 2021 As quality control standards rose across industries, CKW-Group continued to innovate. Our systems were adopted in automotive parts and aerospace. New offices in Ningbo and Wenzhou were launched to better serve regional clients.

- 2022 We successfully entered the capacitor, resistor, inductor, and synthetic diamond industries, achieving stable inspection speeds of over 2,500 pieces per minute. This year also marked the integration of AI deep learning into standard machines for silicone, rubber, and precision metal parts.

- 2023 CKW-Group secured 20 acres of industrial land to build our own intelligent manufacturing campus. Our global business footprint now reaches customers worldwide united by our mission: to ensure every product meets the highest standard.