-

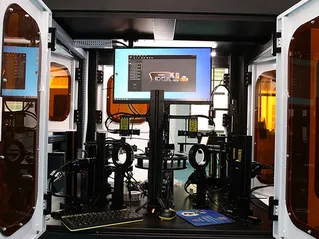

- Ceramic Vision Inspection Machine The ceramic vision inspection machine is purpose-built for high-precision inspection of ceramic components. It features a vibration bowl feeder and a 360° AI-powered vision system, enabling full-surface analysis with exceptional speed and accuracy. Learn more

-

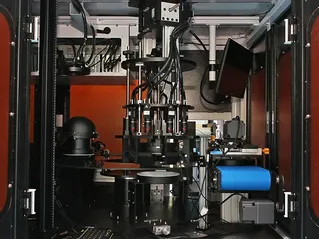

- Powder Metallurgy Vision Inspection Machine The powder metallurgy vision inspection machine is designed for the automated inspection of sintered metal components such as powdered metal bushings and other precision parts. Featuring an automatic elevator feeder followed by vibration bowl feeding, the system ensures consistent part orientation and smooth operation throughout high-speed production. Learn more

-

- Auto Parts Vision Inspection Machine The auto parts vision inspection machine is built for the fast, accurate inspection of small automotive components, such as turned parts. It uses vibration bowl feeding for consistent material handling and is equipped with an AI-powered visual inspection system and 3 industrial-grade CCD cameras. Learn more

-

- Magnetic Material Vision Inspection Machine The magnetic material vision inspection machine is designed for precise, high-speed quality control of magnetic alloy components, such as hexahedral zinc alloy parts. It features vibration bowl feeding for smooth and consistent part handling, and integrates an AI-powered visual inspection system with 4 industrial CCD cameras. Learn more

-

- Plastic Parts Vision Inspection Machine The plastic parts vision inspection machine is engineered for the automated detection of dimensional and surface defects on plastic components. This vision inspection machine features vibration bowl feeding to ensure stable product handling, and integrates AI-based visual inspection software with 5 high-resolution CCD cameras. Learn more

-

- O-Ring Vision Inspection Machine The O-ring vision inspection machine is built for fast, accurate inspection of rubber sealing components across various industries. It uses a vibrating bowl feeder for steady product delivery and is equipped with an AI-driven visual inspection system and 2 industrial CCD cameras. Learn more

-

- Terminal Vision Inspection Machine Achieve reliable inspection of soldering terminals with the terminal vision inspection machine, designed for dimensional measurement and surface flaw detection in high-precision parts. Featuring vibration bowl feeding, AI-powered visual inspection software, and 6 CCD industrial cameras, this system ensures steady throughput and consistent quality results. Learn more

-

- Screw Vision Inspection Machine Designed for precision inspection of cross-head screws, the screw vision inspection machine combines vibration bowl feeding, intelligent visual detection software, and three high-resolution CCD cameras. This system ensures consistent part orientation, efficient processing, and accurate results during high-speed production. Learn more

-

- Connector Vision Inspection Machine The connector vision inspection machine combines an automatic elevator feeder with vibration bowl feeding to ensure efficient and consistent part handling. It is equipped with AI-powered visual inspection software and 7 high-resolution CCD industrial cameras for precise and comprehensive defect detection. Learn more

-

- Gemstone Vision Inspection Machine The gemstone vision inspection machine is engineered for high-precision surface inspection of gemstones and related high-value materials. Using advanced CCD cameras and a precision belt feed system, this system ensures stable and accurate handling of delicate items. Learn more

-

- Button Vision Inspection Machine The button vision inspection machine is specifically developed for the machine vision inspection of sew-on buttons, snap buttons. Equipped with high-resolution CCD cameras and a precision belt feed system, it delivers reliable performance in identifying defects related to shape, alignment, and surface finish. Learn more